Favourite Three

|

Favourite Three – Specialist

Chums  We had crossed the shipping lanes and had

settled just beside Singapore Port Waters, being careful not to go too close. We

looked behind us and in the morning mist was a very special

chum. We love all chums but it’s too hard not to have favourites, here

are three that stood out from the crowd.

Getting closer.

Alongside us but her detail is lost by those around her.

Zhen Hua 25 in all

her glory.

Cruising along at 11.9

knots, she passed in no sluggish fashion on her way to Jeble Ali, a port town 35

kilometres southwest of Dubai, due there in eleven days at eleven in the

morning. She is 234 metres in length, 44 metres wide and has a draught of

8.5 metres. Her deadweight tonnage 49,099.

Her job description – Heavy Lift

Vessel.

Zhen Hua

25 loaded with the new cranes for the Rotterdam

World Gateway anchored off Hoek van Holland awaiting weather improvement before

entering the port in 2013. Her maximum height was a staggering 127 metres. She

was built in 1988 by MHI Nagasaki Shipyard & Engine

Works, Japan and she flies the flag of Hong

Kong.

When launched she was named Ocean Explorer, a name she carried until October 1994. Then she was named Bona Skipper until December 1999. Next Columbia Spirit until April 2005. Yellow Sea until March 2008. Although Zhen Hua 25 isn’t a particularly glamorous name we hope she keeps it as she is part of an impressive fleet of Zhen Hua’s (numbers 8 to 29).   Zhen Hua 25 on other delivery jobs.

So pleased we saw her carrying

cranes.

ZPMC or Shanghai Zhenhua Heavy Industries Company Limited is a Chinese multinational engineering company and one of the world's largest manufacturers of cranes and large steel structures. The company was founded in 1992. It is the subsidiary company of China Communications Construction Company (CCCC). It specialises in designing, manufacturing, erecting, commissioning, shipping in fully erected state, after-sales servicing and developing new port machinery products. Its main products include container cranes (QCs) (supplied eight for London Gateway), rubber-tyred gantry cranes (RTGs), bulk-material ship loaders and unloaders, bucket-wheel stackers and reclaimers, portal cranes, floating cranes engineering vessels and large steel bridge structures.

Off she went. Wonderful.

Taitar No.3 – our second chum is simply beautiful.

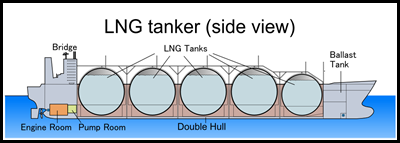

Taitar No.3 is an LNG carrier, a tank ship designed for transporting liquefied natural gas. As the LNG market grows rapidly, the fleet of LNG carriers continues to experience tremendous growth. This lady measures in at 289.5 metres in length, 49 metres wide and she has a draught of 9.7 metres. Her maximum speed is 17.2 knots and she averages 15.7 knots, not bad for her gross tonnage of 118,634. She was built in 2010 and carries the Panamanian flag and is on her way to the Gulf.

The first, Methane Pioneer (5,034 DWT) left the Calcasieu River, Louisiana Gulf coast on the 25th of January 1959. Carrying the world's first ocean cargo of LNG, it sailed to the UK where the cargo was delivered. Subsequent expansion of that trade has brought on a large expansion of the fleet to today where giant LNG ships carrying up to 266,000 cubic metres (9,400,000 cubic feet) are sailing worldwide. Moss tanks (Spherical IMO type B LNG

tanks) Named after the company that designed them, the

Norwegian company Moss Maritime, the IMO type B LNG tanks are spherical in

shape. Most Moss type vessels have 4 or 5 tanks.

The outside of the tank has a thick layer of foam insulation that is either fitted in panels or in more modern designs wound round the tank. Over this insulation is a thin layer of "tinfoil" which allows the insulation to be kept dry with a nitrogen atmosphere. This atmosphere is constantly checked for any methane that would indicate a leak of the tank. Also the outside of the tank is checked at 3 month intervals for any cold spots that would indicate breakdown in the insulation. The tank is supported around its circumference by the equatorial ring which is supported by a large circular skirt which takes the weight of the tank down to the ships structure. This skirt allows the tank to expand and contract during cool-down and warm-up operations. During cool-down or warm-up the tank can expand or contract about 60 cm (24 in). Because of this expansion and contraction all piping into the tank comes in the top and is connected to the ships lines via flexible bellows. Inside each tank there is a set of spray heads. These heads are mounted around the equatorial ring and are used to spray Liquid LNG onto the tank walls to reduce the temperature. Tanks normally have a working pressure of up to 22 kPa (3.2 psi), but this can be raised for an emergency discharge. If both main pumps fail then to remove the cargo, the tank's safety valves are adjusted to lift at 1bar. Then the filling line which goes to the bottom of the tank is opened along with the filling lines of the other tanks on board. The pressure is then raised in the tank with the defective pumps which pushes the cargo into the other tanks where it can be pumped out.  Our

third girl, Asean Protector a Cableship anchored near to

our final corner.

This local, working chum was built in 2002

and flies the flag of Singapore, she is 70 metres in length, 24.42 metres wide,

has a draught of 3.1 metres and weighs in at a gross tonnage of 2,935. She can

trot along at 5.3 knots but keeps to a steady average of 5.1 knots.

I found this interview in Singapore Nautilus

and here is part of it: Captain Dominic Tan, 42, a shipmaster with Asean

Cableship (ACPL), oversees a crew of about 50 on board the Cableship, Asean

Restorer. ACPL (sister to Asean Protector, above), a joint venture of six ASEAN

telecommunications companies, was incorporated in Singapore in 1986 at the

initiative of the ASEAN Sub-Committee on Posts and Telecommunications. The

company repairs and maintains submarine cables around South-east Asia and the

Indian Ocean, and has been one of the leading companies in the submarine

telecommunications fibre optic cable industry. Capt Tan shares with Singapore

Nautilus his experiences of battling rough seas and spending long periods away

from his wife and 14-year-old son.

How did you become a ship captain? What do you love about your job? I have worked in the shipping industry for 16 years, and have been a ship captain for four years. I started out as a deck cadet on board tankers in 1994 after my national service (NS). Because I come from a poor family, taking up the fully-sponsored Diploma in Nautical Studies would not cause any financial burden to my family. I was determined to break away from my situation, and worked my way through the ranks before getting to where I am today. What I love most is the opportunity to travel. Some of the more exotic places I’ve travelled to prior to joining ACPL are the Republic of Congo (Africa), Zhanjiang (China) and Incheon (South Korea). My favourite destination is Hong Kong because of its beautiful coast, and the sight of the city lit up at night. There’s also no need to deal with morning traffic, and I still find myself learning many new and different things on the job every day. What is your typical routine? I am typically away at sea for six to seven months a year. Each commission lasts three to four months, followed by paid leave of one-and-a-half to two months. On a typical workday, I make sure that everything is in good order and that the ship is operationally ready. I also check that the ship’s statutory certificates are in place and ready before we depart. During cable repair operations, my primary role is to plan and coordinate the repair work among various departments, such as deck, engine, cable and subsea. I split shifts with my Chief Officer as the repair goes on around the clock. There are several steps in a repair operation, from locating the actual cable fault to retrieving the faulty cable and bringing it on board, and replacing the faulty section with good cable stock before restoring the repaired cable in position on the seabed. All these steps have to be closely monitored and executed with care, to ensure the cable system runs properly after our repair. I also manage 50 staff from different countries such as India, Indonesia, Myanmar and Malaysia. The different nationalities and cultures can make communication tough at times, but I encourage them to adapt and get along. How do you manage difficult situations at sea? To guard against piracy, we conduct nightly patrols on board, and this includes always putting out our water hoses as a precaution. So far, there have been no piracy attempts on our vessel. We’ve also sailed to Hong Kong during its monsoon season, with swells reaching up to 4m high. Even the most veteran seafarer also became seasick, but with the right motivation, we’ve always managed to overcome rough waters and tough situations. Can you highlight a memorable experience as a ship captain? I remember being tasked, along with my crew, to repair a cable south-east of Pedra Branca and east of Bintan Island in 2012. We were puzzled, as the 7km long cable was missing and couldn’t be located even after two days of intensive searching. It turned out that the cable had been stolen. The fishermen who stole the cable were caught, but because the original cable had been cut into pieces and resold, we re-cabled using spare cables on board our ship. The entire project took about a month to complete! How would you decide over breakfast with a few mates to rob seven kilometres of seabed cable ??? Extraordinary.

ALL IN ALL COLOUR ME ALL SHADES OF IMMENSELY HAPPY AN AMAZING VARIETY OF UNUSUAL SHAPES |