Black Hand Tour

Beez Neez now Chy Whella

Big Bear and Pepe Millard

Sat 8 Nov 2014 23:07

|

Chamber of the Black Hand Mine

Tour

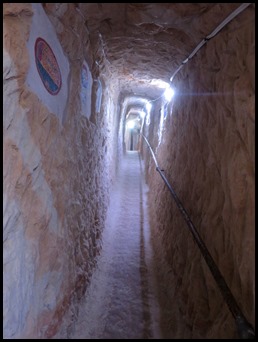

We descended the many

stairs down into the Black Hand Mine and found ourselves in a ‘shop’ that

stretched the length of the first chamber, set up as a jewellers complete with

display cabinets. On the other side lots of information boards and a side room

set up for tea and coffee. Already we were amazed considering five minutes ago

we were up in the heat of day, now in the cool but forty feet down. As we waited

for the others on the tour to pay their entry fees we had a look at some of the

pictures on the wall. The one above, shows the shop

and our first hint that this was to be like no other tour we had ever been

on.

Once we had paid for our tour Jock our guide led us through a gap and on. From the lower

level art chamber – own blog, looking up. Settled with Jock to listen to the life of an opal

mine.

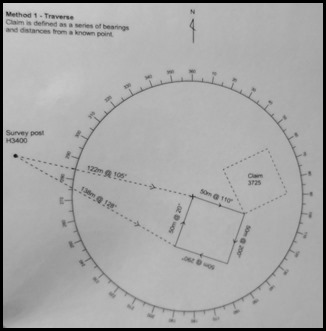

We were fascinated to learn how

people actually came and started digging, all very simple. You find an area

measuring fifty by fifty metres, this can be ‘new

ground’ within the dig area. A previously worked area that is now available or

an area that is currently being dug but up for sale. In recent years a safety

course has been introduced and must be attended before you continue in the

process.

Notes:

Next you go to the

Mine Office and register your area, once the paperwork has been completed

the Office issues a Claim Number,

a map marked with your ‘lot’ and off you

go.

You take yourself, shovel in one hand,

worksheet in the other and fence off your hole or make a metal grid over your

hole.

Then you follow the worksheet which shows you how to support your shaft. Then you become one

of the hopefuls who give the landscape its unique look. The less successful have

their spade, more luck have digging equipment and the

most successful have sorting gear. Next to the piles of ‘slag’ are various

polite notices informing people that should they touch anything they will

shot............and words to that effect. Some live on site with a variety of

old caravans, converted containers, sheds etc. making the whole area look like

some kind of ‘one careful owner’ in the blistering heat – temperatures here can

hit fifty Centigrade. So this particular adventure is not for the city-dwelling

faint hearts.

Here is an article

called Black Bonanza, Dreams of Fire, this gives a good look into the life of a

miner and opal mining: Opal is Australia’s national gemstone, and black opal

is the rarest and most valuable form, at times reaching carat prices rivalling

those of the best diamonds. The Lightning Ridge area in northwestern New South

Wales produces black opal of the highest quality and much of the world’s supply

of darker opal.

“The Ridge” is

famous for red-on-black gems of superlative brilliance in every conceivable

pattern – harlequin, rolling flash, flower garden, picture stone and Chinese

writing. From the deepest, clearest blues and greens to rippling golden orange,

vermillion, carmine and fuchsia, every colour of the spectrum – glorious and

incandescent – is seen in the best of these stones.

Lightning Ridge

is on the edge of the Australian outback, semidesert country with wide horizons,

huge skies and empty blue-grey bush. The geology consists of low outcrops of

Early Cretaceous sedimentary sandstones overlain by Tertiary gravels and

silicates. Black opal is found at depths of three to thirty metres in

fine-grained Finch claystones, which are freshwater channel deposits laid down

more than one hundred million years ago on a coastal floodplain.

During opal

mining, it is these ancient sediments that are brought to the surface and dumped

as mullock heaps, creating the characteristic moonscape of the Australian opal

fields, blinding in the fierce sun.

Lightning Ridge

earned its name around 1870 when a shepherd, his dog and flock of sheep were

struck by lightning and killed – a portent, perhaps, of times to come when hopes

and dreams were ignited by opal flashes in the dark. A few years after that

shepherd met his demise, opal was found at the ‘Ridge, and opal mining commenced in 1901. In this

unforgiving environment where lack of water is matched by the heat and the dust,

the early miners were tough and fearless, sinking mine shafts through

shinecracker – silicified sandstone, with hammer and chisel. The earliest mining

methods were, of course, the simplest and most arduous, pick and shovel,

windlass and leather bucket. Working by candlelight to find the flashes of red

and often rejecting or ignoring the blue-green stones, the old-timers missed a

great deal of the opal, which they discarded along with sandstone, opal dirt and

gravel. It was piled on the surface around the shaft openings as huge mullock

heaps.

The mullock was

reprocessed in dry rumblers in the 1960’s, a time of mechanical innovation on

the fields. By the 1970’s, inventions such as the automatic self-tipping hoist

and the wet puddler enabled faster extraction and finer processing. After the

late 1970’s, processing and washing were further accelerated by the use of

agitators or converted cement mixing barrels. Open cut mining is used less in

black opal country than in other Australian opal mining areas, but by the late

1970’s, the richest areas of the Ridge were being reworked as open

cuts.

Ron’s certificate.

These days, opal

mining claims are fifty by fifty metres, and each miner may register up to two

claims. Miners must complete a safety course before registering a claim, and

mine management training has been introduced.

To start mining,

a shaft roughly one metre in diameter is dug down to the level thought to

contain opal.

Ladders and

lights are secured, machinery is lowered into the shaft and the miner begins

tunnelling. “Drives” and “Ballrooms” are created as the miner searches for opal

along the way. Opal dirt is excavated using jackhammers or machines with names

such as ‘digger’, ‘bogger’ or ‘blower’, many of which are unique to opal mining.

The opal-bearing claystones are brought to the surface by a hoist or blower and

loaded into trucks.

The Processing Dam. The

settling tank of a processing dam contains tons of silt, which dries in the sun

after being washed in modified cement mixers called “agitators”.

At the processing dams, huge

agitator barrels are perched in rows along massive earth ramps. The Ridge is the

only place on earth where opal dirt is processed in this manner, and the dams

are spectacular and mythic sites. Opal dirt is churned and washed in the

agitators using water from the dams. Because of the limited water supply, this

effort is communal. The process can take many hours, depending on the hardness

of the dirt. The claystone wears down into slurry that is channeled into

settling tanks. Eventually only hard material – sandstone and opal – remains in

the barrel.This residual material is emptied onto sorting trays, hand searched

for opal, then left in heaps that slowly weather back into the

soil.

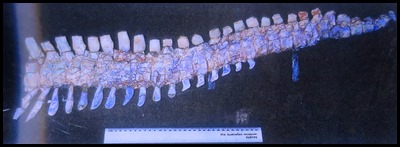

Opal is found in seams, sometimes

there are some amazing finds. “Eric” is probably

Australia’s best known fossil that has been preserved in opal. Found in 1987 by

Joe Vida near Coober Pedy in South Australia, Eric is a pliosaur, a marine

reptile closely related to the plesiosaur. He lives as do the other finds in the

Australian Museum. Vertebral section of the “Ken Harris Pleiosaur” found in 1976 in Ken Harris’ opal

mine near White Cliffs, New South Wales.

Opalised jaw

fragments from the early Cretaceous were discovered at Lightning Ridge.

Steropodon galmani found in 1982. Kollikodon

ritchieri under reflected light and transmitted light to show the detail of

preservation.

Back to our tour. In this particular

mine, the initial hole was dug until it reached a well defined marker between

chalky sediment rock and bedrock. The

opals, if they are there will be found in the layer that my beautiful

assistant is demonstrating. From there test

areas go out like a spiders web – within the claim. It is to be noted

that this mine has yielded $27,000 in twenty five years........

The current active areas within the

mine. Hardwood poles support the newest dig. The inspection hole seemed to go on for a very long way.

This mine must cover many claims and

is a smorgasbord of tunnels and workings. When exhausted as a mine this will over time, no

doubt, become extensions to the art galleries.

A newspaper

clipping showing Ron.

Just a taste of

what we saw on the art front.

I had to have a

little rummage, the claystone was cool to the touch and soft and crumbly

like moist chalk. We loved the moving truck but

simply adored the wheelbarrow with its ruddy

extension.

This is what its all about. The red

fire. Opal.

ALL IN ALL INTERESTING AND

VERY DIFFERENT

SURPRISING AND LIGHT DOWN

THERE |