Knife Making

Beez Neez now Chy Whella

Big Bear and Pepe Millard

Fri 5 Sep 2014 22:57

|

Knife Making, Barrytown

Although we did a fair amount of

research of what we wanted to see and do, along the way people have said bits we

shouldn’t miss, we have found pamphlets in shops and information centres, found

things on the internet and come across things by accident. Bear picked up a brochure for knife making whilst we were in

Greymouth, a new one on both of us. I would very much like to do this, what do you think.

Book us in then, sounds brilliant. Looking it up on Trip Advisor was a first too

– everyone but everyone gave rave reviews, even girlfriends going to keep

boyfriends happy, young and old alike.

We jumped up this morning, drove

ten minutes to Barrytown and were warmly welcomed by Steven and Robyn.

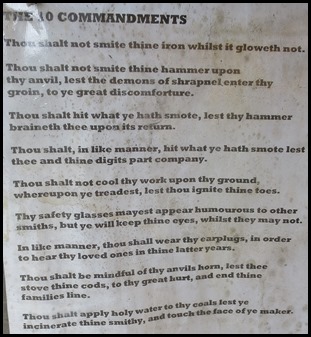

Safety glasses, gloves and overshirts on, Bear had

time to read the 10 Commandments – Smithy

Style.

While we waited for the rest of the

days ‘forgers’ I had time to look at the flowers and

scratch Sam's head.

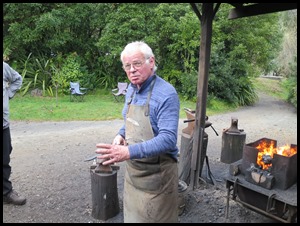

After our safety briefing we listened

as Steven told us how to heat our carbon steel. Three

times we would heat to orange, never banging the tip against the edge of the

forge and not to blue hot. Bear shows how his ‘knife’ began the day and getting

going.

Bear on his final

heat before plunging in bucket – important stage. Mine on final cooling down.

Bear hack

sawing the unwanted end off. Me on third

grind. Bear getting a shiny

middle.

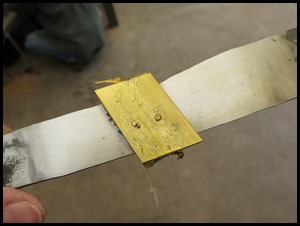

Bear on final

grind. Me drilling my bolster or guard, pins in and off to hammer flat.

Bear cutting his

handle. Both beasts with handles glued and

pinned.

Our last job before lunch was to

masking tape our index finger, get a dollop of three-part epoxy filler and

squidge it all round our handle joins and into our bolster joins, that done it

was hands wash. Bear went to say ‘hello’ to Sam. Our

knives by lunchtime. I went to throw an axe. During our lunch break we

had to consider what we wanted our final blade shape to be. That was easy for me

as I had arrived picturing a machete shape. My last one I had put to a tunas

head and whacked with a hammer and it fell to pieces. I didn’t want anything

fancy to be put away and not used, mine is to live in the cockpit, oiled and

protected of course, kept razor sharp and ready for ‘the catch of the day’.

Easy for me too, I fancied a Bowie

knife.

During our lunch

of toasties and tea Steven worked on. On the beast –

an unforgiving grinder that even he had to wear ear defenders, mask and gloves

for. He would take our knives to first pass. Getting the handles to rough shape,

the blades to the point of ready for sharpening and most important to get rid of

any unwanted epoxy.

After lunch we all

followed Robyn to let the big horses out into their field and the Shetlands for

a bit of a run, jump and fun time. Jess volunteered

to be our runner.

Little One

had a turn but as he was a little lame, just twice. Back we

went – a merry troop chatting. The group of eleven was made up of us, a

helicopter pilot, a sky diver, an anaesthetist, a builder, a school lad, an

engineer and three we didn’t catch. Robyn then was in

charge of getting the swing going.........

Everyone pulled

back, each in turn had the same _expression_, each first words were

different – some unprintable. It is Emma’s birthday

and Lucinda is only six weeks before baby

due.

Bear’s face a

classic. Who would think an ordinary garden swing set much higher off the

ground could be such a short, sharp shock before the rhythm of the swinging took

over.

The Master had done a wonderful job,

our knives were really beginning to look the part.

Now we had to draw felt tip squiggles on each side of our blade and go down in

grinding size three times. Then a piece of masking tap one mil from our bolster

on the handle side. Then we trooped around to the front of the house with

wonderful sea view, flat calm. Robyn took us through 400 and 800 wet sanding, a

1200 dry sand and a metal polish on our blades.

Shy Otto

came out to show off his magnificent hair-do.

The beast was tamed with a smoother belt, taken from the small

selection and Steven put the cutting edge to our

knives.

The final, final

polish.

After we had wood-dyed our handles,

we put them on the numbered newspaper on the draining board. Our lovely line up,

ours are on six and seven. We stood in the kitchen

drinking Robyn’s smashing home-made champagne and watched as Steven put a

protective layer of Kiwi polish on the handles whilst he told us how to care

long-term for our beautiful creations. What is amazing is that ten people began

at the exact same beginning at half past nine this morning and here we were at

five o’clock all with a different finished product – all chuffed to bits. What

an incredible journey of learning, laughter and camaraderie. Not a cross word,

if someone was on a machine someone else wanted, we just lined up and chatted

happily. Robyn and Steven worked flat out ALL day, keeping us busy, safe and

productive. In the morning Robyn came round with a sugar fix of a marshmallow.

In the afternoon with a spoonful of jelly beans. We went from tourists to house

guests and left as friends. A day to remember. We cannot thank Steven and Robyn

enough and hope one day soon they will retire and enjoy some easier days as

twenty three years and thousands of knives is a wonderful career making so many

people very delighted.

Lucinda just made this picture, well her hand and new knife did.

What a fantastic

day. A

brilliant day

ALL IN ALL THE FULLEST, FUN

DAY EVER

A UNIQUE AND TERRIFIC

DAY |