Days in the engineroom

South Pacific Familyadventure 2008

Claes Brodin

Sat 11 Jun 2022 11:51

Planning to do the obvious things ourselves first regarding the fuelsystem, we also contacted M&General Shipyard at St Sampsons bay for assistance if needed. Charging 68GBP/hour+ traveltime we felt the pressure to manage as much as possible on our own.

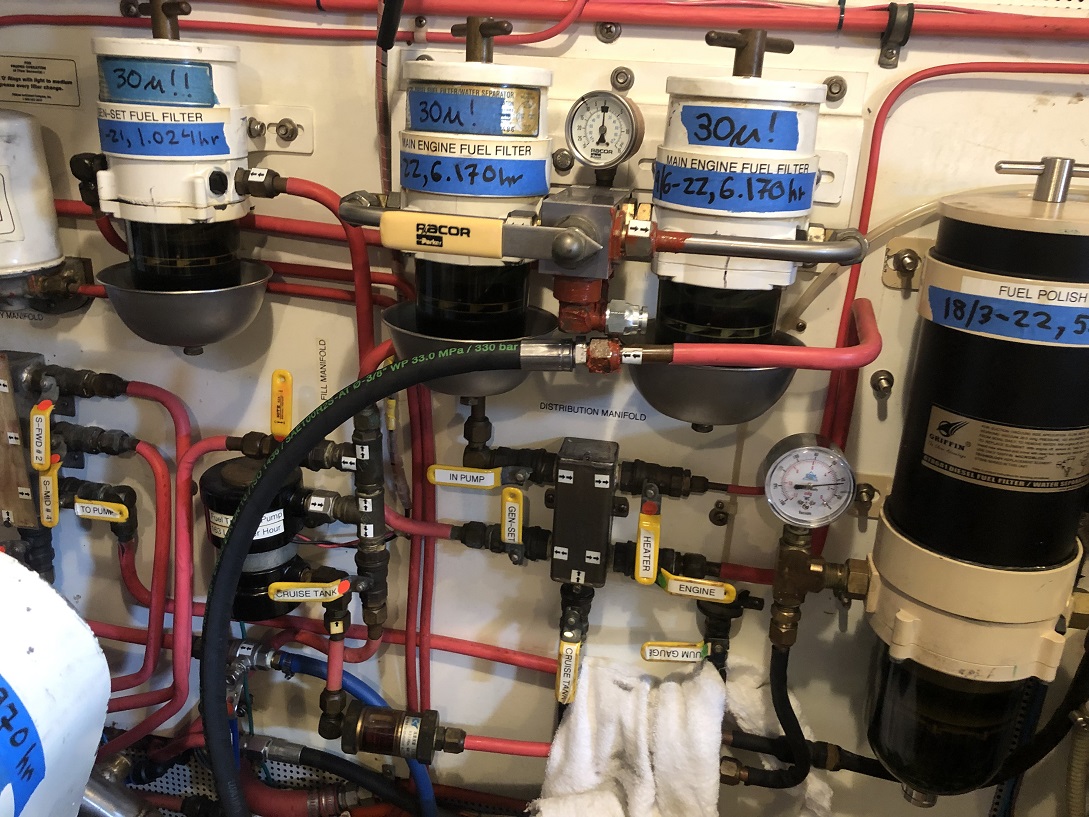

Replacing Racor prefilters (completely clean after more than 200hrs of service),filling up the cruisetank (in case of wrong reedings from the gauge),replacing the fuelpump for a new spare we then bled the system and ran the engine. After less than a minute the floscans started moving up and down followed by stalling.

Day after Nathan from M& General arrived. Looking at a video from the floscan we agreed on the fact that problem was air in the fuelsystem as opposed to fuelstarvation.

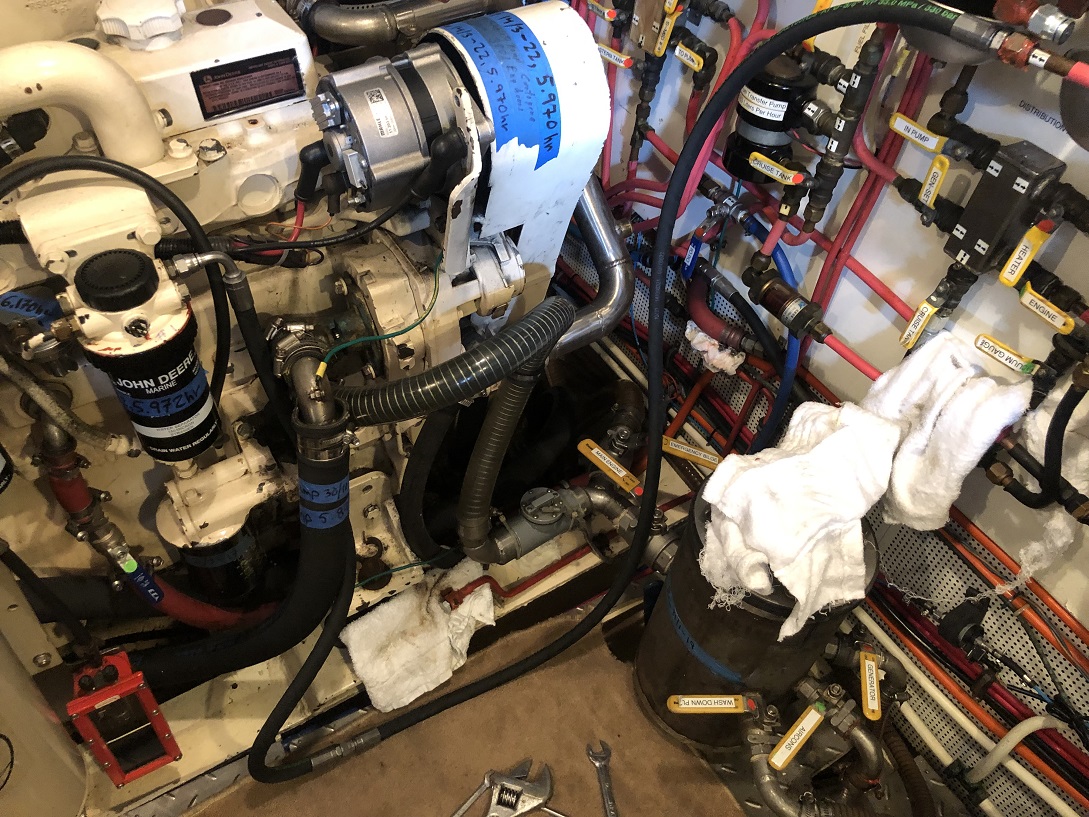

We then decided to bypass the whole Racorunit as well as the Floscansystem to bypass any leakage of air in these two major auxillary systems. New fuelpiping was made by M& General and we then ran John Deere with fuelpiping from the cruisetank suctionline directly connected to the first enginemount filter. After less than a minute John Deere was stalling.

Questions now arose if it could be the dieselinjectior pump (serious) or something from the cruisetank itself as well as it´s suctionline.

Allthough clean Racor prefilters I changed the two John Deere enginemountfilters,replaced the old fuelpiping for the new and reconnected the Racor as well as the Floscan systems. After bleeding the system John Deere has been running flawless ever since.

Of course we were happy but not knowing exactly what was wrong left us with a slight feeling of discontent.