Date: Tuesday 13/05/25 - Time: 17:37 Bermuda time

Position 35:9.57N 50:31.42W

COG 100T SOG 4.3kt, Wind 282T 10

kt,

Temperatures: Air 20C, Sea 20.0 C

Barometer: 1024.3 hPa - decreasing

Sailed distance since departure: 797 NM

Percentage trip: 42.8 %

Last 24h Sailed Distance: 771 NM

Time since departure: 5d 5h 37 m

Average Speed since departure: 6.34

kt

Average VMG since departure: 5.70

kt

Average VMG speed last 24h: 4.99 kt

Intention: sail to Flores

Distance to End on rhumb line: 957 NM

ETA : Tuesday May 20, @ 09:00

Detailed Track:

https://share.garmin.com/svBlueNote

The day started with beautiful blue sky and sun shining.

For the first time since leaving Bermuda we come across other

ships:

a Norwegian oil-rig tug boat and two cargo ships all heading west

and all within one hour.

We set the code-zero that with the 10 kts wind was letting us

sailing at 5 kts.

Then before lunch the wind decreased to 5 kts, so we decided to

start the engine (first time since we left Bermuda -

since solar and wind generator were sufficient to recharge

batteries with energy to spare for heating water for shower)

bring the mainsail down and furled the code-zero in and bring the

code zero down back down.

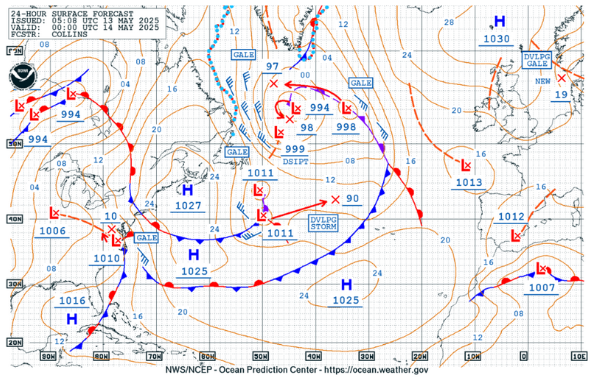

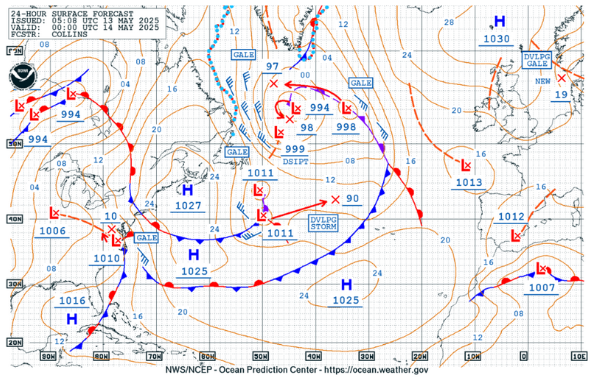

This evening the wind from a deep low pressure up North will start

to affect us and we should be able to go back sailing.

Breakage #1)

As we were bringing down the code-zero we discovered that the

chafing guard of the halyard had broken and only the core was

holding the weight of the code zero.

Unfortunately we could not bringing it down because the chafing

guard was piling-up making the halyard very thick.

So we had to bring the code zero up again and "milk" the chafing

guard (or as it is called in Italian "il calzino") away from the

core.

A process that took more than one hour considering the length of

the halyard.

At the end we were left with the core of the original spinnaker

halyard that will serve as messenger for a new halyard.

Not sure why the chafing guard broke. There was no signs of

chafing.

Three people job trying to remove the chafing guard from the

halyard.

Breakage #2)

As we were working on milking the halyard, in the rolling boat due

to swells, I leaned against the top lifeline and "pop" it broke.

Likely I was fast enough to grab the wood handle on deck and not

fall overboard.

As pictures below shows a clear case of corrosion of the

stainless-steel cable hidden by the plastic cover.

A clear example why nowadays it is recommendation to have

lifelines in either dyneema or cable without plastic cover.

It's possible that the corrosion had happen to a section weakened

several years ago when at a marina that lifeline had hit a pillar

of a dock.

For now we replaced the broken top lifeline with a strong line

(dyneema ?) salvaged from the old life-raft that we had to

disposed in Oxford.

Point of breakage of the lifeline. The plastic was cat a bit to

exposed the cable.

Breakage #3)

When we took the mainsail down we had found a pin on deck. The pin

was holding the the section of the cart that slides in to the fast

track with the section attached to the sail.

We replaced it with a screw and a nylon locking nut. What had

broken (see photo below) is the head of the pin.

Surprising this is from the new doyle main sail that was hardly

used before.

The broken pin holding the two sections of one of the mainsail

carts. The pin head was on the left and is now missing. The pin

also looks a bit bended.

Namiru' e Nairobi eating their lunch.

Synopsis for the North-West Atlantic showing the deep low

pressure system that will bring winds to us but stay well north of

our 35 latitude.