Hard Work at the Boat Lagoon

JJMoon Diary

Barry and Margaret Wilmshurst

Tue 11 Jan 2011 03:51

|

The most significant piece of news is that we have

decided to remain in this part of the world for another year. For one

thing we are not quite ready yet – there are important bits missing from the

engine, the generator does not work and there is trouble with the fridges.

Although it is quite possible that these will be rectified by the time we leave

the marina in about week there will be only another week remaining before

our friends leave with the Thailand to Turkey convoy. To head off for

nearly 3,000 miles across the ocean towards the Maldives and Oman, without

sufficient time to work up, seems too risky. Secondly we are increasingly

attracted to the things we might do here. We shall see whether anybody

would like to visit us for a spot of tropical sailing, we might join a rally

voyaging up the east coast of Malaysia and across to the north of Borneo, we

could make a flying visit to friends in Australia and of course we shall hope to

go home for a few weeks, perhaps in August/September. It begins to look

like an attractive programme.

Looks like seven workers

on board.

It has all been happening on and around JJ Moon.

Mr Samran and his men have done as good a job on the hull and the cast iron keel

as has ever been achieved.

A small repair to the

hull (early stages) and our shiny new windlass and newly sanded

deck.

Mr Samran arrived with

garlands prior to our re-launch and JJ Moon was arrayed to ensure

a successful launch and a safe season.

Mr Phon has been giving the teak decks a major

makeover. The caulking has been routed out, all the teak plugs (hundreds)

have been removed, the screws driven home, plugs replaced, the caulking

renewed and the whole sanded off. It looks as good as new. The work

ethic is highly developed here. Mr Phon is a serious man and a fine

craftsman. His family and other employees arrive on time, work hard and

stay till the end of the working day. They take few days off.

Phon and Nui

Many hands to do meticulus

work

We decided to replace our tatty spray-hood and improve

it by providing a stainless steel frame with a grab handle along the trailing

edge. The best of the local stainless steel workers, Mr Sang, took

measurements and a cash deposit at 1500 on Christmas Eve. At 1500 on

Christmas Day the frame was delivered and fitted, with welds almost invisible,

the steel tubes apparently flowing into one another. Now we are chasing

Muzza the New Zealand canvas worker, also reckoned to be a brilliant exponent of

his trade.

The dinghy has had a new Hypalon tube bonded to the

aluminium alloy floor. Hypalon is a much better fabric than the original

PVC coated polyester and the bits and pieces are also of higher quality.

We now have a superior dinghy but at considerable cost, about which I am all

bitter and twisted.

Christmas was a little strange – with so few signs or

symbols about it was difficult to get engaged and to remember how different it

must have been back home. We had a quiet dinner with another couple in the

local Italian. New Year was more exciting; we were invited to a beach

party in the north of the island. The seafood was good, the company

interesting, the fireworks and firecrackers numerous and deafening and at about

midnight we launched our own hot air filled lantern to join the hundreds of

others drifting romantically out to sea.

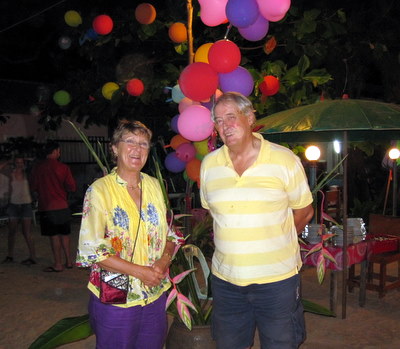

New Year festivities on

Nayang beach

Preparing to float our

Chinese lantern assisted by Pamela

We are now back in the water. Launching off was an

operation infused with quiet drama – in the manner of a small funeral for a

highly respected citizen. We had been warned to be prepared for 1300 so it

was a bit of a surprise when at 1100 there was of roaring of diesel, the shadow

of the mighty hoist passed across the windows and the foreman’s special hat

appeared above the stern. “We hang you in the slings now. Go at one

o’clock.” “Oh, OK” The boat was swarming with deck workers, the

engineer was below and now the anti-fouling men came back to touch up the

patches where the cradle had supported the hull. At about 1200 everybody

disappeared for lunch and silence crept over the yard. After a bit I

climbed down the dodgy ladder and sat on a wall in the shade. The boat

hung, out of her element, giving a slight creak every now and again. At

1305 there was a general stirring and purposeful movement led by the fork

lift truck which was to remove the cradle and lumber. The uniformed team

walked determinedly towards their stations led by the foreman in his

special foreman’s suit and hat. The big diesel started with a roar and

belch of dirty smoke. The leviathan moved off accompanied by the tolling

of a dolorous warning bell. At the sound of the bell security guards

appeared from nowhere to pull temporary barriers across each end of the road to

prevent interference by dis-respectful traffic. At funereal pace the

cortege rolled solemnly towards the dock, the foreman leading under his hat,

each of the mighty wheels watched over by its own official guardian and the

owners close behind like chief mourners. Out over the dock and the

boat was lowered gently in the slings. Soon it was “Right, fire her

up Skip” (actually in Thai, but I got the message), our engineer leapt

below to ensure that the important bits fitted that morning did not leak, the

slings were unhitched and dragged ashore, lines were cast off and thumbs

raised all round. A nudge forward into gear and away we went towards our

newly allocated berth. JJ Moon was back in her

element.

Travel

hoist foreman. |