Mallorca

|

Getting

to Mallorca We

anchored overnight in Cala Son Saura then headed for Alcudia in Mallorca (37

miles away), motoring in company with Hilary and Paul (PAX NOSTRUM).

Towing

B&B to Mallorca.

PAX

NOSTRUM. Boarding

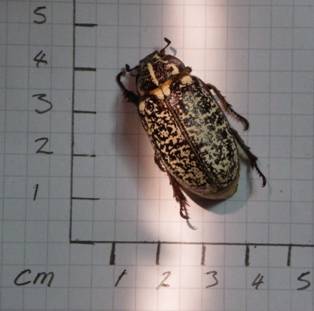

by beetle In

the anchorage in Alcudia we were boarded by an extremely large beetle that

walked up the dinghy painter – including the bit underwater – to

get to us. I am ashamed to say (out of ignorance and fear), that we sprayed

him/her with fly spray. We had a good look on the internet, but weren’t

able to identify him/her, so if there are any entomologists out there who know

what type of beetle this is, we’d love to know. There is a happy ending

– he/she was obviously big enough to withstand the effects of the fly

spray, and after a couple of days in a beetle-coma, started walking around

again, so we let him/her go in the boatyard.

The

beetle boarding via the dinghy painter. Getting

rid of the Klingons We

had been looking for somewhere to haul out as the seals in the leg (the bit

that the prop hangs off) went a while ago (letting water in to mix with the oil

there) and we needed to change them – and to antifoul. Come on, the last

time CAPE was antifouled was in Pwllheli before we launched her in 2007! As the

price for a lift and few days on the hard in the boatyard in Acludia wasn't too

bad, we came out on the Wednesday, with a lift back in provisionally booked for

the following Saturday morning. PAX hauled too as Hilary and Paul had a problem

with their stern gland packing (stops water coming in through the hole where

the prop shaft goes out). [Editor’s note: that last bit is dreadful

English – suggestions on a postcard please...] We

scraped off the barnacles and had CAPE’s bottom power-washed. We did 3

coats of antifoul, getting up before the sun to paint while it was cool. David

changed the leg seals, replaced the bolts in the engine mounts (3 had sheared),

and changed the prop (again, for a go-faster one). As we had access to fresh

water, we washed all the laundry. The generator had stopped working the week before

– something to do with the mother board falling over (Karen and Richard

on PYXIS had had the same problem with their generator, so we had an idea what

the problem might be). As we were not going anywhere for a couple of days, we

got the piece for the generator sent out and fitted. Unfortunately we

weren’t quite ready for the lift on the Saturday morning, so we rebooked

one for the Monday.

CAPE’s

slimy bottom emerging from the water.

Power

washing the slime off.

One

of Bryn’s jobs was being let loose with cans of spray paint to remark the

anchor chain.

David

replacing the generator mother board.

CAPE’s

very smart and slippy bottom – black is so slimming don’t you

think? Just need to remove the masking tape... Who

put seawater in the engine oil? We

were ready to go back into the water on the Monday morning when David checked

the oil in the main engine and found thick, grey gunge instead of oil. We

cancelled the lift. Now we know that the oil had been fine 25 engine hours

earlier, so the problem had occurred since we had left Mahon. We were lucky to

have found it before the engine seized, and then to have found it before going

back into the water. We were also lucky that Paul is an engineer, so while he

and David worked through all the potential causes, I transferred onto PAX to

help Hilary finish antifouling PAX. The

boys ruled out the oil cooler and the head gasket. With no other obvious causes

of seawater in the oil, we took out the engine and sat it on the concrete

alonside us to let the gungy grey stuff drain out. I can’t believe how

small the engine is – to have caused us so much trouble!

Taking

the engine out

“If

you put your hand on that wheelie bit on the front Paul, and I poke my finger

in here, maybe that’ll sort it.” The

boys continued to dismantle bits of the engine, clean them, put them back

together and pressure test them as appropriate. The evidence started to point

to the seawater pump as the probable cause of the problem. We ordered a new

head gasket. The solenoid fell off the starter motor, so we had to buy a new

starter motor. Paul remade the dipstick as this got ripped off when the engine

came out. With

a bit more time and 240 V power, I set up my new sewing machine and restitched

the UV strip on the genoa, made more mozzie nets for the hatches, and mended

all the tatty flags and ripped shorts. We washed everything on the boat that we

hadn’t washed before including all the towels, bedding and cushion

covers. With the patch of concrete next to us set up to live on, a tarpaulin

overhead as a sun shade, and me hanging washing out to dry on ropes between the

boats it looked like the 'pikeys' had arrived! I think we were the only people

living on and working on a boat in the yard -- it's very posh here and most

people get work done for them. Having said that, the yard and the staff were

really helpful and professional. Cambered concrete with gulleys down the side

to collect run-off water/antifoul, and a recycling centre the like of which I

have never seen: ·

containers

for used oil ·

a

separate container for the containers that used to contain the used oil ·

containers

for paint ·

a

separate container for the contaminated tins ·

separate

containers for different sorts of batteries, aerosols, scrap metal as well as

the usual glass, plastic and paper. The

containers were emptied regularly, and a man with a van sorted the metal and

took it away. A far cry from Messolonghi Marina where waste oil is left with

the general rubbish, there is no recycling, and all noxious liquids (antifoul

and blackwater) are dumped into the “eco-zone” lagoon. Perhaps it

is the environment that pays the true cost of a “cheap” marina?

Restitching

the UV strip on the genoa.

Drying

the washing in the CAPE ‘pikey’ camp. Working

in the boatyard in the heat was tough – it was 32–33°C during the

day and didn’t drop below 29°C at night. No sea breeze also meant more

mozzies. It was lovely on the boat – the cockpit was covered in oil, we

couldn't use the loo (we used the marina toilets during the day and a bucket at

night), and everything had to be winched up and down (including the pee bucket)

using a pulley and we had to climbing up and down using a ladder (that wasn't

quite long enough) – a bit like living in a caravan suspended 3 metres

above hot concrete. It

wasn’t all bad. We had a BBQ one evening but didn't want the boatyard

staff to know what we were doing (we were sure it wouldn't be allowed, lots of

expensive boats to go up in flames and lots of flammable liquids around) so we

ended up putting the BBQ on a shopping trolley on its side to stop it scorching

the concrete.

The

“Trolley-Barb” (patent applied for).

A

little night music. Terry

and Emma (LIBERTINE) scooped B&B off on a bike ride to the local nature

park to see the wildlife – mainly cows and birds, apparently, but

including a cow with egret on its back (just like you see in documentaries

about wildlife in Africa). B&B

were great -- doing boat jobs in the morning then taking themselves off to the

beach in the afternoon. They did a physics project on simple machines -- there

were so many examples in the boatyard and they had a great time researching the

machines and taking photos of examples that they could see around them. We

found a bar with relatively cheap beer and live music.

Bryn

did a solo spot with Country Roads and a borrowed guitar and earned

himself free drinks for the duration of our stay. Eventually

PAX was ready and she went back into the water.

PAX

all ready to go.

PAX

safely back in her natural element (Bryn picked an appropriate T-shirt for

boat-bottom work). We

played music in the Titanic Bar (conveniently placed behind us in the

boatyard) and got the locals involved.

In

the Titanic Bar. Eventually

David worked out what was the cause of the seawater in the oil. The oil/water

seals between the sea water pump and the engine had closed up. There needed to

be a gap between them to let water out if a seal went, otherwise the water

would be pumped into the engine – which is what happened. Paul and Hilary

collected a head gasket from the not-so-local auto parts dealer (they have 2

motorbikes on board, so they can reach otherwise inaccessible little places),

the head went back on, the engine went back in, and the floor went back down in

the cockpit. The engine was reconnected, but we had to wait until we were back

in the water before we could test it.

The

engine going back in.

The

cockpit with the floor up and the engine back in place. B&B

cleaned the engine room up (for a fee).

B&B

in the engine hole, cleaning. 10

days after being lifted out, CAPE went back into the water, the boys finished

connecting things and started the engine...

CAPE

back in the water. This

is what is called a cliff-hanger. We’d like to thank Imray Laurie Norie

& Wilson Ltd who are kindly sponsoring us by providing charts and pilots

for our trip www.imray.com. Thanks to everyone who got in touch to tell

us that they follow our blog. If there’s anyone else out there who would

like to get in touch, please e-mail us comments and questions to smith dot cape

at gmail dot com. © 2010. All materials (text and photographs)

in this blog (unless stated otherwise) are the property of Sarah and David

Smith. Copyright and other intellectual property laws protect these materials.

Reproduction or retransmission of the materials, in whole or in part, in any

manner, without the prior written consent of the copyright holder, is a

violation of copyright law. __________ Information from ESET NOD32 Antivirus, version of virus signature database 5325 (20100730) __________ The message was checked by ESET NOD32 Antivirus. http://www.eset.com |