Kulhudhuffushi

Vega

Hugh and Annie

Sun 13 Mar 2022 11:40

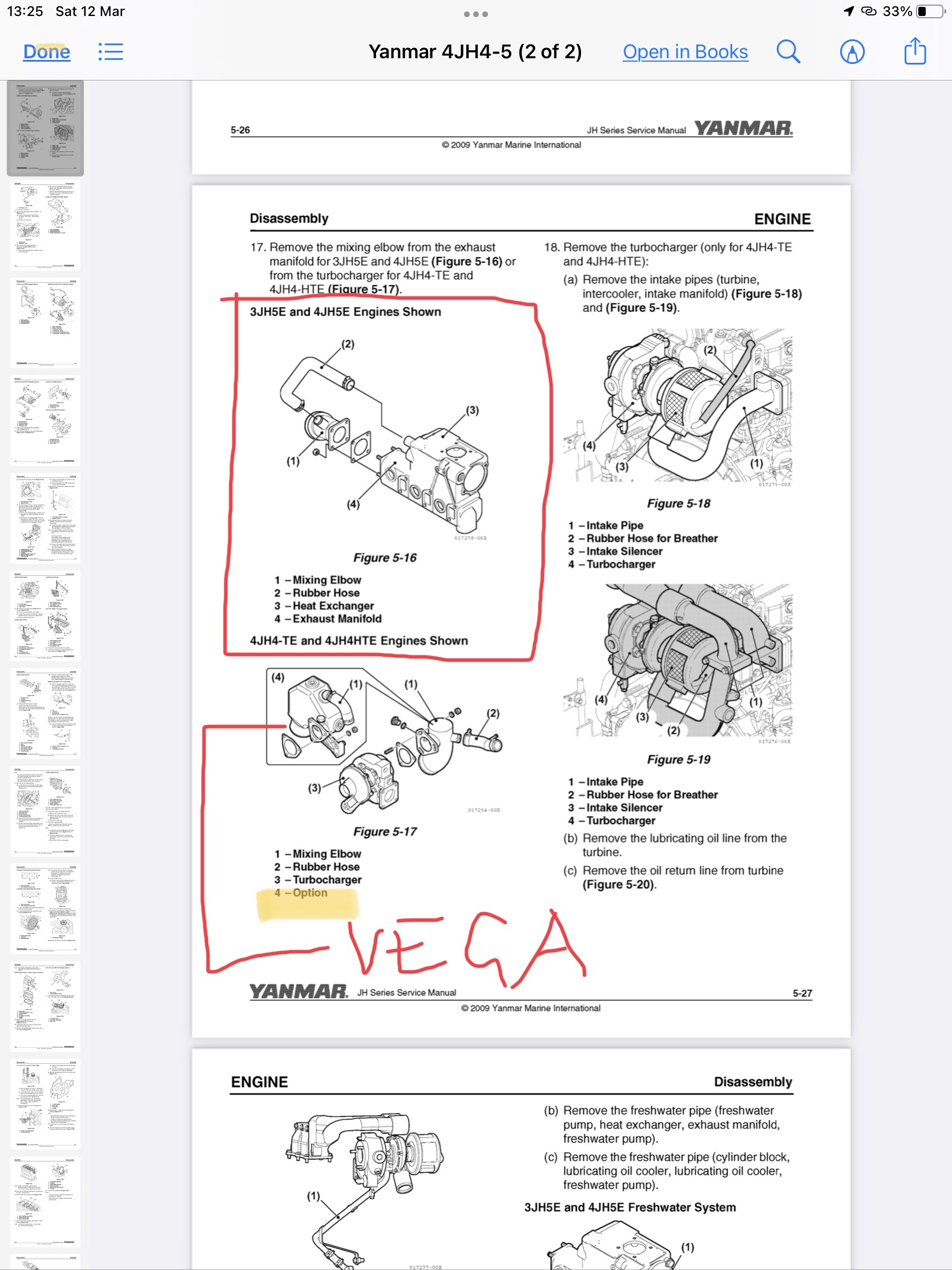

06:36.90N 073:4.00E Our moment of paradise was brief. One day only to visit the nearby village, walk along the beach and to organise our tow down to Kulhudhuffushi. Enough to know it is a wonderful anchorage (5m water over sand) that we reached by using Google Earth to follow our position through the pass, avoiding the shallow reef and coral bommies. The village is lively and friendly and we enjoyed watching an inter-school match of girls handball - with no dispensation from hijab for the young players. We arranged through Assad for a tow at 0900 the following morning and sure enough three guys arrived on the dot. We had two lines, one from each stern quarter of the towing vessel that we put onto our bow cleats. We then pulled up the anchor by hand (easier than we had imagined) and were gently pulled over the reef. At which point we realised it was low tide and with limited room for manoeuvre we hoped the guys in front knew what they were doing. They did, and with less than a metre to spare under the keel we slid over of the reef and into deeper water. As we approached Kulhudhuffushi a swell was running and Vega surged forward and then slowed as each swell passed. The guys towing slowed right down and made allowance for this motion with little overall loss of speed. Boat handling is so impressive when carried out by those who really know what they are doing. Less than two hours after leaving our anchorage we were slowly pulled up to the harbour wall where our lines were taken by two port operatives, looped around the large bollards, handed back to Vega and we were tied up. Even before our lines were secured the towing boat had left and there was no chance to properly thank the guys and pay them. Presumably our agent fixer Assad will sort this. In the afternoon a marine engineer called Kanburu arrived to take an initial look at the engine. I had been unable to turn the engine using a socket spanner on the crankshaft pulley retaining nut. It didn’t feel like the engine had seized but I was unable to turn it more than a little. I therefore suspected water in one or more of the cylinders. We dipped the oil to see if water had got into it and caused it to emulsify. The dip stick showed no oil at all! This was a puzzle because I had dipped it when we were at our anchorage and there was both oil and no sign of water contamination. Kanburu considered this a major problem and to deal with both the loss of oil and leaking coolant the engine would have to come out and go to his workshop. He would come back later that day and carry out proper testing to determine the scale of the problem. Now, when cruising and faced with broken equipment on your boat, modern communication ensures that there will be no shortage of advice to hand. In my case this includes Colin and Jon following up behind us, all those using the various Facebook sailing sites we belong to, other sailors we keep in touch with on Messenger groups, friends and family, and Craig who owns C&C Engineering in Phuket and who did all the work on our propshaft. Craig advised to remove the dipstick and wait for at least 10 minutes before dipping the oil. This I did and, lo and behold, the oil proved to be there after all! Kanburu failed to show later that day but did come the following morning along with his cousin. They removed the fuel injectors and, as predicted by Craig, managed to turn the engine and squirt black, oily water out of the cylinders and all over the engine compartment. Furthermore there was water in all three cylinders. Kanburu diagnosed a problem with the cylinder head gasket but even I, along with our online army of advisors, thought that water in all the cylinders might be unlikely with just a leaking head gasket. We agreed to try and source a head gasket set both in the Maldives (Assad) and abroad (me as a back up). We also agreed that as the oil seemed to be ok the engine could be worked on while still in the boat (ie the work would be on the top of the engine). In Moslem countries Friday is the equivalent of Sunday but I became anxious when Kanburu didn’t come back as expected and make further investigation of the engine problem. This turned out to be a misunderstanding on my part and the time given for coming back was not for the Friday. All was sorted over a friendly and helpful WhatsApp exchange in the evening (Kanburu was happy to sign up in order to keep in touch with us) that included the fact that Kanburu would arrange additional battery charging for us as we are now solely reliant upon the solar panels (this merits a separate post you will be thrilled to learn). The day was not wasted however and I arranged for Craig to send over a new head gasket set. I thought it would be one gasket but no, there is one for every part removed during the removal/replacement sequence. Also, from the advice given by my advisors plus studying the engine manual, I now know more about the Yanmar 3JH5E cooling system than I could ever have imagined I would. I feel I should share this with you but I do realise there are limits to your forbearance . Further explanation of the engine problem does however require me to impart some of this knowledge. On a Yanmar engine the engine exhaust gasses leaving the cylinders are channelled into the exhaust manifold tube leading to the exhaust pipe and out of the boat. The manifold tube is encased within the heat exchanger which is an enclosed water bath holding the coolant and is the equivalent of the radiator on a car engine. The exhaust gasses are cooled before onward flow into the exhaust. The coolant is pumped through the heat exchanger and also down to a “calorifier” at the back of the boat which is in effect another heat exchanger within the domestic hot water tank. Running the engine produces hot water and at the moment we have no means of preventing this - another issue that will be rectified through the installation of cut off valves on the heat exchanger. A leaking coolant pump or hot water calorifier can be a source of coolant loss. The temperature of the coolant is monitored and if it gets too high triggers the alarm that we experienced. It can also force open a pressure valve in the filling cap to release pressure in the form of hot, expanded coolant and steam (another potential source of coolant loss). The coolant is itself cooled by pumping seawater through a series of small diameter tubes that are in a self contained removable unit within the heat exchanger. The seawater absorbs heat from the coolant when the coolant heats the pipes through which the seawater is flowing. After the heated seawater and cooled exhaust gasses leave the heat exchanger they are brought together in a mixing elbow that is designed to prevent the seawater back flowing into the engine. The elbow can corrode and fail to prevent this back flow and so regular replacement is a maintenance item. In our case, when I asked for the elbow to be replaced in Thailand, we were advised that we have a non standard bronze elbow that should last a lifetime and therefore shouldn’t need replacing. So a likely and not uncommon way for coolant to get into all the cylinders is from a leak from the heat exchanger into the exhaust manifold. When the engine overheated it was still running. The problem with water in the cylinders only arose after refilling the heat exchanger while the engine was stopped and when there was no flow of exhaust gas to prevent the back flow of coolant. Yesterday Kanburu removed the heat exchanger and within minutes of returning to his workshop reported a major leak where the aluminium of the exhaust manifold had corroded through at the join with the heat exchanger casing - see photo below. The heat exchanger is now at the Volvo workshop in Male where they can weld new aluminium over the leak and rebuild the wall of the manifold tube. The gasket set is on the way from Thailand and it is possible both will be at the boat in two or three days time for replacement and reassembly……….. The corrosion problem we have encountered is not unusual, however Craig doesn’t stock replacement coolant assemblies as re-welding of the aluminium manifold is the usual remedy. We could source a new unit from the UK but if the repair is likely to be good enough to at least see us back to Blighty then there seems little point in shipping one all the way out here (I am sure you will be remembering these words for future reference). One lesson learned is that if a marine engine is left for any extended period without use it must be flushed through with fresh water and the coolant drained unless it can be run up from time to time. This particularly applies in tropical climates and we know of at least three other boats that have had a similar problem. If only we had known then that there is a marine engineer at the yard in Thailand who could have done this for us. Also we suspected there was an issue with the loss of coolant when back on the water in Thailand. There was no external evidence of a leak and temperature testing of the engine showed this to be normal. With hindsight I should have pushed for (or even carried out myself) a pressure test on the heat exchanger. |