Banaban Oil

Beez Neez now Chy Whella

Big Bear and Pepe Millard

Thu 2 Jul 2015 22:57

|

Our Visit to the Banaban Coconut Oil

Factory

No visit to Nuku would have been

complete without a visit to the tiny building to watch the half a dozen

welcoming and happy workers at the Banaban Virgin Coconut Oil Factory. So little

we forgot to take its picture, so instead, the billboard

poster taken at ‘the bus terminus’.

We walked a few dozen strides back

from the bus depot and as we neared ‘the factory’ a lady whipped her music

producing ear buds out, extended her hand and cracked massive smile. Such a

welcome “Come, come, where are you visiting from”. The small building was in two

halves, the left – the goings-on side, the right – storage and the office. In

between was covered walkway set up as the de-fuzzing

on one side and cracking on the other. The coconuts used here seemed to be small, no bigger than Bears

fist, “yes, we use a hybrid here”. The weeny whose job it was to crack the

coconuts wielded her machete as if it were a butter

knife.............

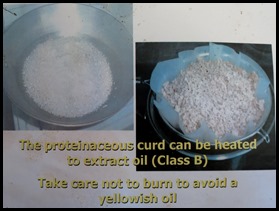

Now inside the left-hand building we

could see the spin-grinder machines used to remove

the white flesh, called Splitting.

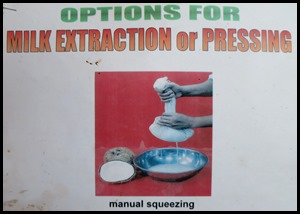

Next, the removed flesh is cold-pressed and the fluid is

sieved three times, each through an ever finer mesh.

On the work bench was a pile of soap, I particularly like the star shapes that were formed

in a jelly mould. Sadly, we couldn’t buy any as it wasn’t ‘tidied up’ or

packaged. Surprisingly it had no aroma at all, wasn’t sticky and was quite

solid.

Through a door, we were in the long

drying room.

All the empty

shells are piled in one corner and fed into the fire

below, a happy chap turns the pressed flesh with a trowel to ensure even

drying.

It takes just a half an hour to turn

the moist chippings into the dry

darker shade, this is then bagged and piled at the

back by the flue, This will be sold to the locals for one pound sixty a

sack, used to bulk up pig fodder.

Back through the splitting and soap

room we passed through the ‘bits and bobs’ store

room.

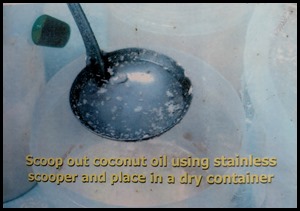

Outside our guide

showed Maj the nearly finished product.

I nipped back and took the last of

the process pictures.

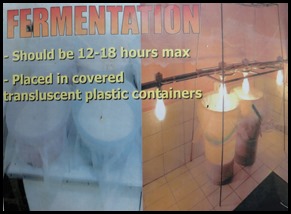

Standing out in

the sun, the last of the ‘bits’ are skimmed off and after three weeks

the clear fluid is ready to be bottled. Perfumes can

be added at this stage.

We bought a Sandalwood Body Oil for

three pounds and Coconut Oil for one pound thirty, this can be used in cooking

or a couple of spoonful’s can be taken “to keep you regular, if you are having

problems not going”........ We then said our fond farewells and thanked to this

great bunch of happy workers. Time for a snack

before hitting the pier.

ALL IN ALL A JOYFUL VISIT

AMAZINGLY SMALL-SCALE

INDUSTRY

|